Unlocking Potential: Aftermarket Components as a Cost-efficient Option for Machinery and Heavy Tools

In the ever-evolving landscape of machinery and hefty devices maintenance, the utilization of aftermarket components has arised as a compelling alternative worth checking out. These elements, commonly forgotten in support of initial equipment manufacturer (OEM) parts, present a cost-effective remedy that calls for attention. While the concept may elevate eyebrows amongst reactionaries, the advantages that aftermarket components offer in terms of price financial savings, top quality, and performance are not to be undervalued. As markets seek ways to maximize procedures and make best use of performance, the potential unlocked by aftermarket components poses intriguing opportunities that can improve well established practices and produce substantial benefits.

Expense Financial Savings and Worth Recommendation

The cost financial savings and value suggestion of utilizing aftermarket components for equipment and heavy devices are substantial variables that add to operational efficiency and economic practicality in different markets. By opting for aftermarket components over initial tools supplier (OEM) parts, services can realize significant price savings without compromising on quality or performance. Aftermarket parts are usually more competitively priced than their OEM counterparts, enabling firms to reduce maintenance and repair work costs while still making certain the proper performance of their equipment and devices.

These components are widely offered and provide a broader option compared to OEM components, giving companies with better flexibility and benefit in sourcing the components they require. Furthermore, aftermarket components are understood for their high top quality and reliability, conference or even exceeding sector standards in many situations.

Top Quality and Compatibility Assurance

Highlighting the paramount value of high quality control and compatibility confirmation is important when thinking about the application of aftermarket components for equipment and heavy equipment. Ensuring that aftermarket parts fulfill or surpass market requirements for top quality is critical to keeping the optimal performance and durability of the equipment. Quality guarantee actions, such as strenuous screening treatments and certifications, supply peace of mind to devices owners that the aftermarket parts will function dependably and effectively.

Boosted Accessibility and Choices

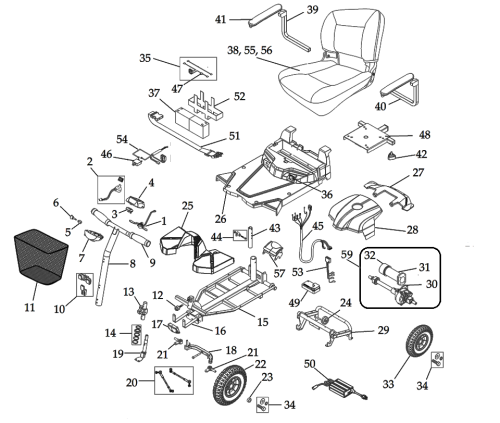

With a broadening market and growing need, aftermarket parts for machinery and heavy tools are currently offering raised schedule and a wider series of alternatives to provide to the varied requirements of equipment proprietors. This surge in schedule is driven by the aftermarket parts market's commitment to fulfilling the certain requirements of different machinery brand names and models. Tools proprietors can now access a large array of aftermarket components, varying from engine elements to hydraulic components, electrical see this website systems, undercarriage parts, and a lot more.

Moreover, aftermarket parts suppliers are continuously broadening their product lines to include parts for a wider series of machinery and heavy tools, guaranteeing that proprietors can find appropriate replacements regardless of the equipment kind or version they possess. This boosted schedule and variety of aftermarket components encourage equipment owners to make economical choices without compromising on top quality or performance. Consequently, they can effectively preserve, fix, and update their machinery with self-confidence, knowing that aftermarket parts use a reliable option to OEM elements.

Performance and Toughness Benefits

Enhancing machinery and hefty devices with aftermarket this link parts brings significant efficiency and sturdiness advantages to tools proprietors. Aftermarket parts are commonly made with innovations in technology and materials, offering improved performance contrasted to initial tools manufacturer (OEM) parts. Updated parts can cause raised power, performance, and overall device capabilities, bring about boosted performance and functional performance.

Moreover, aftermarket components are regularly crafted to be extra durable and long-lasting than their OEM counterparts. This enhanced resilience can translate to reduced downtime for maintenance and repairs, inevitably conserving equipment proprietors useful time and cash. By investing in aftermarket parts known for their toughness, machinery and heavy devices can stand up to severe operating conditions and hefty work with higher resilience.

Basically, the efficiency and longevity benefits of aftermarket parts add substantially to enhancing the performance and longevity of equipment and hefty equipment. Tools proprietors stand to acquire an one-upmanship by leveraging aftermarket options to improve the total performance and longevity of their possessions.

Sustainability and Ecological Impact

The application of aftermarket parts not just boosts the performance and durability of equipment and heavy tools but additionally plays an essential role in dealing with sustainability issues and lowering environmental effect. By selecting aftermarket components, industries add to the reduction of waste generation considering that these parts are typically sourced from recycled materials or with remanufacturing procedures. This practice straightens with the principles of a circular economic situation, where resources are used successfully, and see it here waste is reduced.

In addition, aftermarket components can extend the life-span of equipment and tools, decreasing the regularity of substitutes and subsequently lowering the general carbon impact related to making new machinery. Furthermore, the manufacturing of aftermarket components usually entails much less energy usage and fewer discharges contrasted to manufacturing initial devices manufacturer (OEM) parts - Bobcat Aftermarket Parts. This shift to aftermarket parts sustains environment-friendly techniques by promoting reusability and source conservation within the commercial market. Eventually, the integration of aftermarket components right into machinery maintenance and repairs is a sustainable approach that benefits both businesses and the atmosphere.

Final Thought

Finally, aftermarket parts use a cost-efficient remedy for equipment and hefty tools by supplying cost financial savings, quality control, enhanced schedule, efficiency advantages, and sustainability advantages. These parts not only supply a viable alternative to initial tools producer parts but likewise add to the overall performance and long life of equipment and tools. Welcoming aftermarket parts can cause substantial price financial savings and enhanced performance, making them a valuable choice for businesses seeking to maximize their sources.

By choosing for aftermarket parts over initial equipment maker (OEM) components, companies can realize considerable cost financial savings without endangering on top quality or efficiency (Bobcat Aftermarket Parts). Tools owners can currently access a large range of aftermarket components, ranging from engine parts to hydraulic parts, electric systems, undercarriage elements, and extra

Moreover, aftermarket parts suppliers are continuously broadening their item lines to consist of parts for a broader array of machinery and heavy devices, ensuring that proprietors can locate ideal substitutes no matter of the devices type or model they possess. Aftermarket components are frequently developed with innovations in innovation and products, offering improved efficiency compared to original tools supplier (OEM) parts. Furthermore, the production of aftermarket parts often includes less power usage and less exhausts compared to making initial devices maker (OEM) components.

Comments on “Contrast Premier Bobcat Aftermarket Parts for Improved Machine Efficiency”